Maasai Stoves & Solar stove

Firebox model

The ICSEE stoves draw smoke out of the home while efficiently providing heat for cooking and household comfort. The stoves successfully remove smoke while keeping flame and after-burning smoke and gases engaged in the cooking process as long as possible. They attain high combustion efficiency and clear household air, while keeping children safe from burns.

Replacing three-stone indoor cooking fires with this stove reduces local deforestation and carbon emissions by sixty percent. It reduces smoke in the houses by ninety percent. Read about the impact of these stoves.

Stove improvements

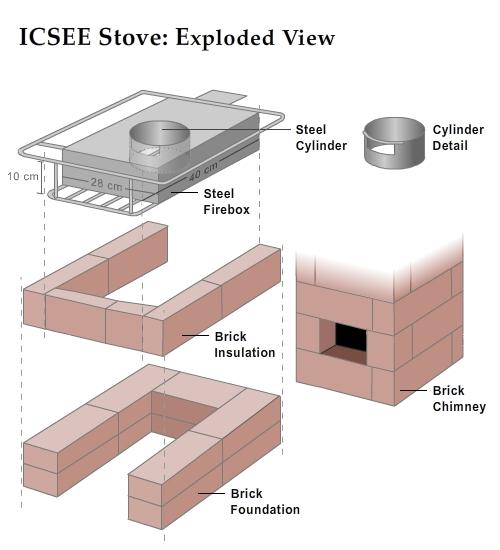

The ICSEE designed the firebox of the first stove in 2011, followed by three significant design improvements. In 2014 the ICSEE doubled the thickness of steel where any bending or cracking had been observed in stoves used for two or three years. With this improvement we can expect stove life to reach well beyond five years.

At the time of this improvement, the stove still had five bricks cemented inside the firebox with special heat- resistant mortar. This defined the path for the smoke and hot gases moving to the chimney, while insulating the sides of the firebox to make it safe for children. However, due to long-term exposure to the hot gases, these interiors became potential places for deterioration.

In 2015 we designed innovations to eliminate this potential weakness. Instead of putting bricks inside the firebox we narrowed the firebox and placed the insulating bricks alongside.

And as an added bonus, in the new freed space at the front of the firebox, we established a space that the cook could fill with water during cooking. This allowed her to heat water without requiring an additional pot. However, because we stay in close contact with the village women who have our stoves, we learned that they didn’t often use this new feature. And it has a drawback of leaving the front of the stove without brick insulation. The brick had kept the sides of the stoves cool and safe.

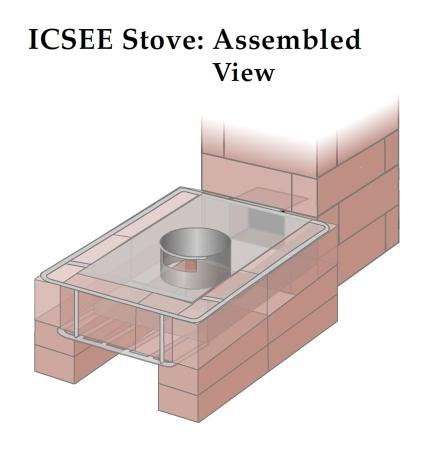

Therefore, in our most recent design, illustrated here, the water space is eliminated. We put bricks across the front for good insulation all the way around. We now manufacture and distribute this design version.

Read about our stove features.

Stove materials

We use a mortar that is a mixture of sand (four parts) cement (one part) and lime (one part). This particular mortar is stable at high temperatures. The stove, firebox and chimney are made from materials purchased from local businesses, and include bricks, metal sheets, sand, cement, lime, and rebar.

Built from bricks by the Maasai Women’s Installation teams, the chimney rises up through the roof , extending at least one meter, and is placed against an interior wall. The teams use clay as mortar inside the house. Where the chimney is exposed to moisture near the roof and outside; they use sand and cement mortar. The bricks are not too hot where they penetrate the thatch, so there is no fire danger. Where it extends above the thatch, the chimney is a pipe of thin metal. A rain guard of sheet metal tops it, and it easily opened for sweeping.

The area of the chimney’s internal shaft is 14 x 14 cm. About 12 cm from the floor, at the front of the chimney, there is a hole opening into the chimney shaft 10 cm high and 15 cm wide. The chimney also has a brick-sized side hole at floor level for cleaning out ash. After cleaning, the hole is closed with a brick.

The firebox is approximately 46 x 24 cm horizontally, and 11 cm high. We manufacture steel pieces from 2 mm stock and cut a 21 cm diameter hole in the top and bottom of the firebox. There is a steel cylinder, welded between the holes in the top and bottom of the firebox. At the front of this cylinder and where it is attached to the firebox top there is a reinforced hole of approximately 5 x 15 cm.

The stove in use

When the stove is in use, the burning gases come up from the burning fuel through the bottom hole. They pass through this hole in the cylinder into the firebox and along its sides to the chimney. The firebox has an opening in the rear where the hot gases can exit into the opening in the front of the chimney. With the firebox and chimney sealed together with mortar during installation, this connection is closed to the outside.

When the stove is in use, the burning gases come up from the burning fuel through the bottom hole. They pass through this hole in the cylinder into the firebox and along its sides to the chimney. The firebox has an opening in the rear where the hot gases can exit into the opening in the front of the chimney. With the firebox and chimney sealed together with mortar during installation, this connection is closed to the outside.

We weld a rectangular frame of heavy rebar to the top of the firebox. It extends out the front and sides by the width of a brick. The Maasai women installers line up the bricks along the front and sides of the firebox, supported by the stove foundation and under the rebar frame. These bricks provide insulation so that the front and sides of the firebox are cool enough to prevent burns.

The team mounts the firebox on a brick foundation so that firewood can be introduced and burned beneath it. Our design includes bricks at the back of the foundation that block the flames from going directly through the chimney. Instead, they go up, strike the cooking pot, and leave by the hole in the front of the cylinder.

The cook puts the cooking pot over the hole in the top steel piece of the firebox. The flame comes up through the hole in the bottom steel piece and heats the pot that is right above this flame. The pot prevents the smoke and gases from entering the room, The steel cylinder, welded between the two steel top and bottom pieces, forces the gases to take a circuitous path to the chimney. It is this circuitous path that creates stove efficiency, keeping the burning gases away from their exit through the chimney long enough to provide efficient cooking.

International Collaborative for Science, Education, and the Environment

International Collaborative for Science, Education, and the Environment